Marlin: A Firmware for 3D Printers

Muhammad Yamin

Faculty of Agricultural Engineering & Technology, University of Agriculture, Faisalabad, Pakistan

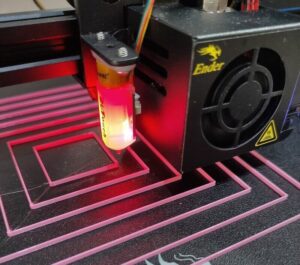

Marlin firmware stands as a hub in the realm of 3D printing, coordinating the safety features and precision controls. In this critical exploration, we delve into the firmware’s prowess, particularly focusing on power loss recovery, bed leveling using a BLTouch sensor, and its robust safety mechanisms.

Power Loss Recovery

In the unpredictable world of 3D printing, a sudden power outage could spell disaster for an ongoing print. Marlin firmware addresses this vulnerability with a robust power loss recovery feature. It’s important to note that Marlin’s power loss recovery functionality may requires hardware-level compatibility with the specific 3D printer’s electronics. Marlin utilizes the SD card to store information about the last layer successfully printed. In the event of a power loss, the printer can seamlessly resume from the last recorded state, preserving both time and material. This ingenious approach ensures that a momentary glitch in the power supply won’t condemn hours of meticulous printing.

While automatic power loss recovery is the default behavior, Marlin offers users some customization options which allow the users to define and integrate custom M-code scripts into their printing profiles.

M413 S0: This M-code disables the power loss recovery feature entirely.

M413 S1: This M-code enables automatic power loss recovery as described previously.

When M413 S1 is set in Marlin during a print job executed from the SD Card or Flash Drive, the system consistently saves the ongoing print job’s state at intervals to the SD Card / Flash Drive. In case of a machine crash or power outage, Marlin provides the option to resume the print job from where it was interrupted. Even without a power-loss detection circuit, this feature functions by periodically writing the recovery file, typically once per layer. However, when a POWER_LOSS_PIN is set, Marlin adopts a more refined approach, writing recovery information only upon the actual detection of a power loss. This method is preferred because it ensures the print resumes precisely from the interruption point, avoiding repetition of the last layer. Moreover, it significantly reduces wear on the SD card or Flash Drive.

Bed Leveling

Bed leveling is a pivotal aspect of achieving precise and flawless 3D prints. Marlin firmware takes this task to new heights, integrating seamlessly with a bed level sensor like proximity or BLTouch auto-bed leveling sensor. The sensor, typically mounted to the print head, probes multiple points on the print bed, adjusting the Z-axis in real-time.

The integration of bed level sensor with Marlin offers a user-friendly and highly accurate bed leveling process. This synergy results in improved first-layer adhesion, reducing the risk of print failure. The meticulous attention to bed leveling underscores Marlin’s commitment to elevating the overall printing experience.

Safety Features

Beyond power loss recovery and bed leveling, Marlin firmware places a premium on user safety. It incorporates various safety features designed to mitigate risks and enhance the overall reliability of 3D printing. One notable safety feature is thermal runaway protection. This guards against potential catastrophes by shutting down the printer if it detects a significant deviation in temperature. This not only protects the printer from potential damage but also prevents safety hazards. Moreover, Marlin includes endstop and software limit checks, preventing the printer from inadvertently moving beyond its physical constraints. This proactive approach minimizes the risk of mechanical damage during operation.

Vibrant Community Support

Marlin firmware’s strength extends beyond its technical features. It boasts a vibrant community offering invaluable support for users of all levels. This community fosters knowledge-sharing, troubleshooting assistance, and collaborative development.

Key Resources:

Official Marlin Website (https://marlinfw.org/): Comprehensive documentation, configuration guides, and troubleshooting tips.

GitHub Repository (https://github.com/MarlinFirmware/Marlin): Access the latest code versions, report issues, and discuss with developers and other users.

Community Benefits:

1. Collective problem solving by sharing your challenges, find solutions, and benefit from shared experiences.

2. Get help tailoring Marlin to your specific needs through community-developed configurations and plugins.

3. Contribute to Marlin’s evolution by reporting bugs, suggesting features, or even developing your own code improvements.

This highly engaged community fuels Marlin’s continuous improvement and adaptability, making it a preferred choice for both novice and experienced enthusiasts in the ever-evolving world of 3D printing.

In conclusion, Marlin firmware emerges as a cornerstone in the 3D printing landscape, showcasing its prowess in power loss recovery, bed leveling with BLTouch sensors, and a suite of safety features. Its ability to autonomously handle power interruptions, seamlessly integrate advanced sensors, and prioritize user safety underscores its indispensability for both novice and experienced 3D printing enthusiasts. As technology evolves, Marlin remains a stalwart, continually pushing the boundaries of what is achievable in the dynamic world of 3D printing.

This comparison helps a person to choose a software for 3D according to his need and considerations. As a student who is just a beginner will choose repetier while a professional expert will choose Marlin which help to deal with complex problems

This article contain most advanced information and I have learned more about new things by the help of it. (Muhammad Ahmad)