Variable Rate Technology: A Review (Part 3)

Muhammad Yamin

Faculty of Agricultural Engineering & Technology, University of Agriculture, Faisalabad, Pakistan

In recent years, the agricultural landscape has witnessed a profound transformation fueled by advancements in precision technology. At the forefront of this revolution stands variable rate sprayer technology, heralded as a beacon of precision agriculture. Following research studies reveal significant advancements in variable rate technology.

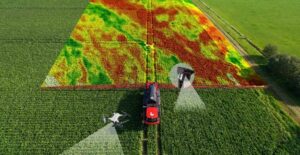

Dou described that variable rate sprayer is one of the true representatives of precision agriculture. It has made great progress in development of precision technology in recent years. This research elaborates characteristics and principles of variable spray technology. It also highlights the results obtained in the development variable spray technology in automatic control, target detection and spray application. Target detection technology is defined as it is automatic target detection technology which is based on real time sensor and another technology named as automatic targeted spray technology which is based on GIS technology. In spray technology field, the research and application of nozzles are described. Variable spray technology development direction and application prospect is forecasted.

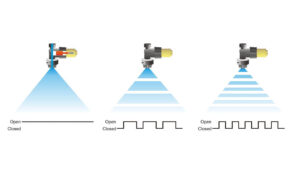

Sharda developed an Automatic Section Control (ASC) which leads to economic savings whereas minimize the environmental influences. Though there is restricted data concerning nozzle flow dynamics, once shutting ON and OFF boom sections or nozzles and therefore the potential impacts on application precision and validity. On that account, an exploration to judge the system response to cope with period of time, nozzle off rated associated to flow rate consistency across the boom, was regulated for ordinary agricultural sprayers victimization ASC. For commercially offered individual nozzle and boom section management, an 18.3 m sprayer was outfitted. Tests were carried to imitate sprayer moving out of purpose rows into a no spray area then return into spray zone by specifying two purpose row eventualities having twenty and seventy degree angles. Ten high frequency response pressure detectors were irregularly launched over the boom to live nozzle pressure. To compute the nozzle flow rate retard, subsiding time, percent off rate (the distinction between attested and selected flow rate) and nozzle flow uniformity (CV) considering solely ON boom sections, the nozzle pressures were permuted to nozzle flow using the correlation of pressure and flow. It was indicated by results that nozzle flow rate settling time changed from 0.4 to 14.4 s and off rate of nozzle between 36.6% and +28.7% for 70 point row auto-boom tests when exiting and returning point rows. Nozzle flow uniformity (CV) was greater than 50% for a short duration (<1.0 s) when returning point rows, during all tests. Compensation testing for twenty points row reentry highlighted the control system constraint to respond definite situations where feedback response times could not match target rates rapidly set for the controller. Overall results indicated that system response time can impact nozzle off-rate and can vary with point row angle.

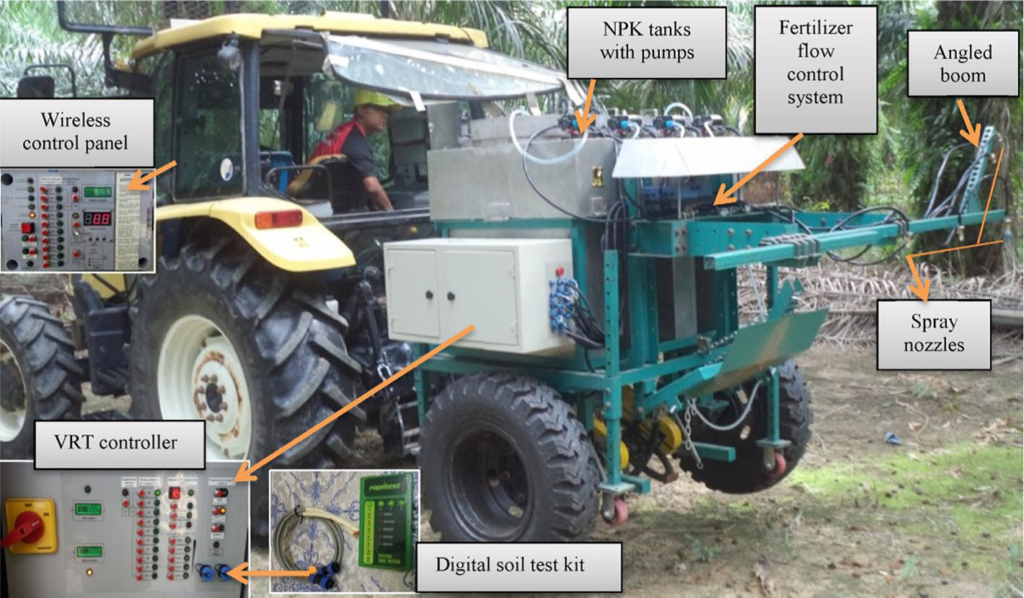

Sindir concluded that the application of fertilizers is one of the most vital operations in the agricultural yield. Fertilizer is applied traditionally in the whole farm irrespective of variations across the land. Randomly taken soil cores throughout the field are mixed to form a single sample. This sample is analyzed and a unique fertility is recommended in accordance with the results. Moreover, zone sampling is done to evaluate the variability in soil fertility of farm land with this new technology of precision agriculture. Fertilizer are applied in this grid zones according to their requirement with the help of this technology. In this study economics of variable rate sprayer is assessed, partial budget analysis is done to conclude the appropriate conditions for farmers.

Tekin studied that in recent past years, agricultural researchers has been mainly focusing on to increase the yield by applying lower but effective production input such as sprayers, fertilizers and seeds. In this regard, during last ten years, new technology called precision farming has been introduced which is aimed at sustainable, environmental friendly and an economical way of production of crop. Fertilizer application is one of the most essential operation in the crop production. The main requirement to get benefit from variable rate fertilizer is to achieve uniformity and to apply accurate amount of fertilizer. In this research, variable rate fertilizer applicators uniformity and accuracy of application is evaluated. To get best distribution and accuracy of variable rate applicator is also discussed.

Womac stated that the current innovation associates with an organization for fluctuating flow command for accurate implementation such as agrochemical applications. The discovery is administered in vicinity of a flow control device encompassing a metering rod flexibly arranged within an enclosure. The posture of the metering rod is manageable so as to manage the flow rate, flow angle or drop size of liquid passing through the flow control instrument of the current innovation.

Through meticulous examination of automatic flow control mechanisms, nozzle dynamics, and precision application methodologies, above studies elucidate the transformative potential of precision agriculture. By optimizing resource allocation, minimizing environmental impact, and enhancing operational efficiency, variable rate sprayer technology is poised to revolutionize farming practices worldwide. As we embrace the era of precision farming, the findings of this research pave the way for a more sustainable and prosperous future in food production.