Variable Rate Technology: A Review (Part 2)

Muhammad Yamin

Faculty of Agricultural Engineering & Technology, University of Agriculture, Faisalabad, Pakistan

Continuing our exploration of Variable Rate Technology (VRT), we probe deeper into its multifaceted applications and transformative potential in modern agriculture. Building upon the foundations laid in Part 1, we will examine additional case studies, advancements in sensor technology, and innovative approaches to precision farming. Join us as we uncover how VRT is reshaping farming practices, optimizing resource allocation, and paving the way for a more sustainable future in food production.

Anglund investigated ground sprayer field performance to apply chemicals at variable and constant speed rates with both injection sprayer and pressure based technology. Variable rate application system was evaluated by quantifying field application accuracy via system instrumentation to monitor sprayer chemical flow, sprayer speed and sprayer location in the field .Collected data was useful to provide information to determine sprayer application rate for each variable and constant rate application. An average application rate was produced by application system within 2.25% of required application rate.

Fulton described that to apply granular fertilizers and lime of agriculture, spinner spreaders is popular to use. More interests in variable rate technology has also made aware about distribution and accuracy of these spreaders. This research was conducted to evaluate distribution application of variable rate spinner fertilizer spreader. Distribution application was evaluated with the help of procedures which are given in ASAE standard S3421.2. Variable rate and uniform tests were carried out to describe spreader variability and to test rate changes effect with the help of GPS. A sigmoidal function described changes in increasing rate of application. While a linear function was used to illustrate decline rate changes. Both high and low application rates were modeled with the help of average transverse patterns. Resulted models were then matched with actual distributions. The model accurately described variable rate and uniform application patterns. Hence, this would be suitable for simulating variable application errors.

Gil described a system and a method to determine fluids atomization characteristics emitted by a nozzle. In one epitome, nozzle emits a fluid while simultaneously vibrations occurring with the nozzles are sensed. These vibrations are used to give information about fluid atomization characteristics. Sensed vibrations are compared with vibration patterns produced via known fluid by similar nozzle, tested atomization fluid characteristics can be predicted. In one epitome, for example, fluid atomization can be determined as a function of flow rate or velocity by nozzle.

Nuyttens described agricultural spray characteristics relate to most important factors that affect spray drift, spray coverage, deposition on the plants. So, nozzle type effect, pressure on spray, size and characteristics of spray was also studied in the context of a research project of agriculture related to spray drift. The aim of this research was to produce a test ring and a protocol for the description of spray nozzles using PDPA. While PDPA means phase doppler practice analyzer. This test ring could measure velocities and droplet size based on principles of light scattering. It was consisted of spray unit, climate room, a three dimensional automatic positioning system and one dimensional system PDPA. Velocity characteristics and droplet size of various nozzle-pressure combination was determined and then compared with obtained results of researchers by using various measuring procedure and techniques. The nozzle type effects, pressure and size on droplet size and velocity spectra were clearly shown by test results.

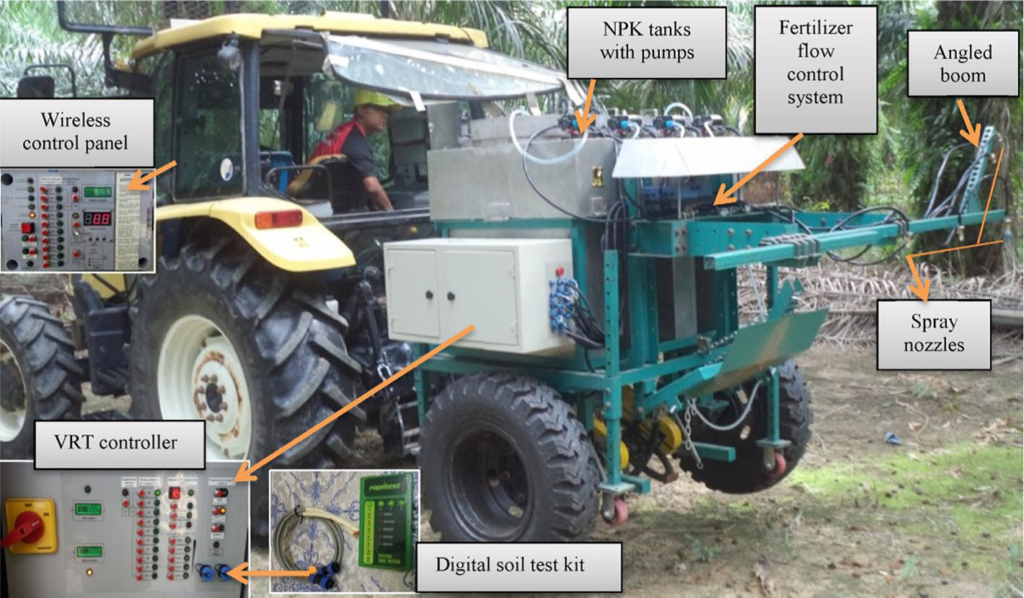

Yamin conducted research on VRT liquid fertilizer applicator. This study illustrated that application of nutrients for soil management with the help of sensor based VRT liquid fertilizer applicator is suitable. This technology can be used to save time and resources but proposed design of VRT has to fulfill the nutritional requirements of tree and cereal crops like paddy and oil palm. Soil fertility sensors, flow control valves, pressure sensor, speed sensor and flow sensor are involve in this dedicated design of VRT. Variable fertilizer flow is compensated with increasing speed of machine. Data can also be transferred from electronic control to outer computer via this design. This data is transferred to computer for record and to test performance of machine by calculating errors in machine and lag times. This machine was originally designed for tree crops but this can be operated for cereal crops with some modifications. It includes three DC pumps of 5L/min flow and 6.89bar pressure with flow lines of 6mm internal diameter. It was revealed in simulation that system could achieve 0.06L/s at 13.73m/s velocity.

Through a comprehensive review of case studies and technological advancements, we’ve witnessed how VRT is revolutionizing farming practices, from precision spraying to fertilizer application. The integration of advanced sensors, data analysis techniques, and innovative design approaches has enabled farmers to optimize resource allocation, minimize environmental impact, and enhance crop yields. As we continue to unlock the full potential of VRT, it’s clear that its transformative impact will pave the way for a more sustainable and prosperous future in food production.