Variable Rate Technology: A Review (Part 1)

Muhammad Yamin

Faculty of Agricultural Engineering & Technology, University of Agriculture, Faisalabad, Pakistan

Imagine farming with pinpoint precision. No more wasting precious resources on areas that don’t need them, and no more environmental impact from excess fertilizers and pesticides. This isn’t a futuristic dream, but the reality of Variable Rate Technology (VRT). By using advanced sensors and data analysis, VRT is transforming agriculture, allowing farmers to tailor inputs like fertilizer and weed control to the specific needs of every zone within a field. This means increased efficiency, boosted yields, and a lighter footprint on the environment. Let’s review VRT and explore the exciting ways it’s revolutionizing the agriculture.

Alamouti conducted a research on variable rate sprayer by installing electronic control system on conventional sprayers. This research was based on direct injection type electronic solution control system. This system included tank having chemical, pump for metering chemical, metering driver of pump, metering pump’s speed sensor, implement travelling speed sensor, electronic control unit (ECU), a GPS receiver and mixing unit. An EC sensor was placed on extreme right nozzle of the sprayer. Solution of brine was filled in chemical tank. System time response was calculated at different concentration change rate of solution, working pressure and travelling speed. There was 1 % variability in system time response only on working pressure.

Hu stated that chemical utilization ratio can be improved by using variable rate technology, variable rate technology is also used to reduce the chemical waste. In this study, a variable rate spraying system was developed based on canopy volume. The system was generally made up of ultrasonic sensor, PC, single chip, mechanism of flow control and nozzles. Distance between sensors and canopy foliage were measured using ultrasonic sensor. Detected data of sensors was sent to computer via single chip for further processing. Flow rates of the nozzles were adjusted by flow control mechanism. Software and hardware design were introduced. Installation position designs, connections and hardware choice was included in hardware design. Designs of system operation interfaces and flow charts were introduced in the software.

Ishak evaluated that the development of sprayer system which controls the quantity of spray based on amount or percentage of weeds. In that sprayer system camera vision are fit which detect the weeds with help of electromechanical system. The detection of weeds was based on green color. The electromechanical system was used to control opening and closing of valves. The sprayer system was able to be developed by the combination of the electromechanical system, the controller, PC parallel port relay board, and visual basic programming software. The result of application was determined when the spraying operation was done in the filed whether at which percentage the opening and closing of nozzle was done, it closed at 2% and half opened at 3%, 50% and fully opened at 51%.

Mooney demonstrated that VRT is variable rate technology that has the potential to increase the yield and rates and lowering the input cost which is the basic key of profit. This technique is useful as it identifies the input requirements, which vary from field to field i.e specific sites input rates and their applications to the field. VRT uses two methods of gathering the information of specific sites for the input applications, Map-based and sensor-based VRT. Sensor based VRT systems were found to have high ownership costs but low recurring annual costs. But in Map-based, it offers a high annual costs and lower ownerships. The profitability of these two VRT systems is based on the inputs varied and the level of input savings.

Sharda demonstrated that a splitting or cutting control capabilities are minimized with application on unwanted areas by modern spray controllers combined with DGPS receiver. Accuracy of application of fertilizer and pesticides can be improved by this technology. Active system answer for spray gun involving cycling and spontaneous switching was not checked. Hence study had been conducted. A procedure was performed to develop and then perform practical to evaluate end pressure and flow of system. Adjustment to a basic agricultural sprayer that equipped by a controller providing both nozzle control and boom section. A triple test protocol was established to measure dynamics inflow during the nozzle control and boom section. Simulation moods cannot be obtained via simulation schemes and spray controllers under both flow compensation. The rate of system flow and pressure of nozzle tip on boom position had been measured and analyzed to measure the flow and pressure variations. The results showed that methodology of test produced enough data that can be used to analyze the end pressure of nozzle and system. The controlled test and pressure varied from 6.7 to 20%. But further tests are needed for better performances of agricultural sprayers.

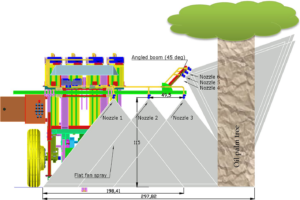

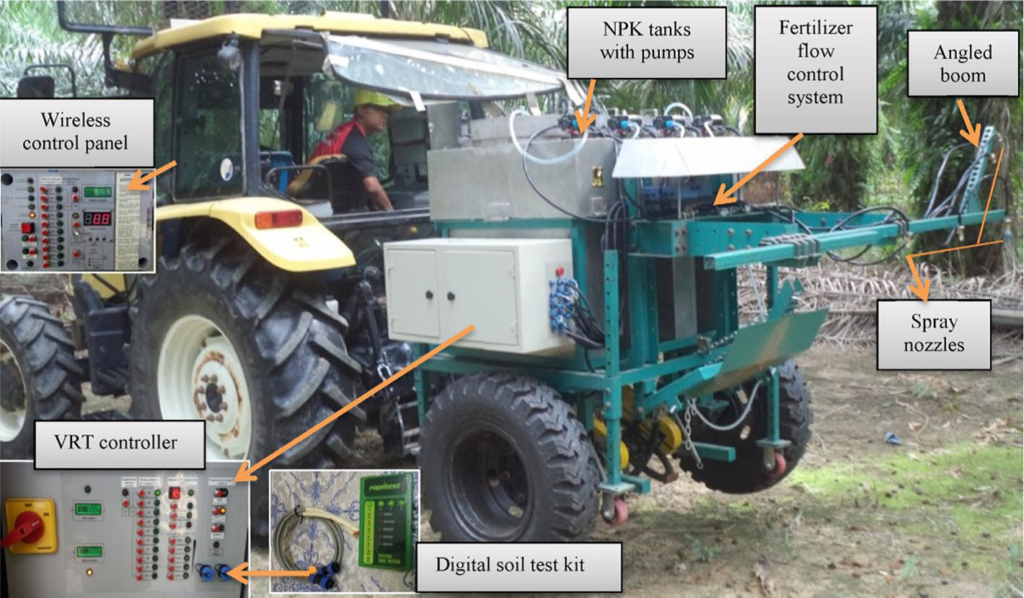

Yamin developed a variable rate liquid fertilizer applicator tailored for the specific needs of oil palm cultivation. The system was system capable of assessing the NPK status of soil and applying nitrogen (N), phosphorus (P), and potassium (K) nutrients individually and at variable rates. These nutrients were delivered in the form of aqueous solutions of single-nutrient fertilizers. The design incorporated a fertilizer flow control and spray system engineered to administer liquid fertilizer precisely around the oil palm trees, focusing on a targeted area of 25 square meters, corresponding to the most effective roots. Through simulation and calculations, six 8006 flat fan nozzles were carefully selected to ensure optimal swath coverage during fertilizer application. Nozzles 1-3 are vertically mounted on a horizontal boom to target the machine side of the oil palm tree, while nozzles 4-6 were positioned at specific angles on a 45-degree angled boom to spray across the tree’s canopy using a trajectory method. Simulations indicated an average liquid velocity of 14.05 m/s from each nozzle, effectively covering a distance of 2.5 meters across the tree.

Zhang developed a variable rate fertilizer to control amount of fertilizer using NDVI of the crops. This system was included six sensors mounted on the front of the tractor. They are module interface, hydraulic motor, micro controller, speed sensor, rotation which told amount of fertilizers needed for the crops. Results showed that error was less than 5.17 % and fertilizer’s response time was 0.875 seconds, which could meet need of practical production.

The above studies conclude that VRT holds immense potential for a more sustainable and profitable future of agriculture. Further advancements in sensor technology, data analysis, and application methods promise even greater efficiency and environmental benefits. As VRT continues to evolve, it has the potential to revolutionize agricultural practices, leading to a more prosperous and sustainable future for food production.

Need of the time to save input cost and enhance the crop yield.

Advanced form that can give help to the farmers.

This article demonstrates benefits of VRT in increasing efficiency, reducing waste, and improving crop yields.(less input cost and high yield).

Chaging the future.

Wonderful information.

This article demonstrates benefits of VRT in increasing efficiency, reducing waste, and improving crop yields.(less input cost and high yield).